Search term must have more than 2 characters.

Specification

ski lift effective transport distance | 300 - 600 m |

drive and return bullwheel diameter(rubber lined) | 2.5 m |

distance of ropes along the line | 2.5 m |

sheave trains | with catchers and signals indicating rope slippage and location |

sheave diameter | 200 mm |

tensioning | hydraulic, self-acting |

carriers | double, hydraulic |

drive output range | 22.0 – 45.0 kW |

haul rope | Ø 16 - 18 mm, galvanised steel |

conveying speed | inspection 0.5 m/s, continuously adjustable 0.5 – 3.2 m/s |

capacity | max. 1440 persons/h, effective 1200 persons/h |

surface finish of steel parts | hot-dip galvanized |

Technical description

Drive terminal

This terminal is mostly placed at the bottom and is used for tensioning and passenger embarking.

It consists of a load bearing steel structure, hydraulic haul rope tensioning system, an engine with a gear box and anti-roll back device a drive bullwheel, guide sheave trains and leading sheaves.

The steel structure consists of a supporting column anchored in a concrete slab, a super-structure with sheaves and a sliding beam to which the drive unit with the bullwheel is bolted. Also mounted onto the super-structure is a beam with sheave trains and beams with guide sheaves.

Hydraulic system - double-acting hydraulic motor - is seated between the fixed and sliding sections of the drive terminal. The hydraulic unit is seated on top of the supporting column.

The drive bullwheel is seated on the gear box output shaft. It is a weldment with spoke bracing and a rubber lined groove. There is a safety rim at the bottom side of the wheel to prevent the rope slipping and also to stabilise carrier assembly.

As an option, the terminal can also be delivered as a disembarking terminal, and/or as a fixed one and placed at the top.

Return terminal

It is mostly fixed and placed at the top and serves for disembarking.

The steel structure consists of a supporting column anchored into an independent concrete slab, compression braces and arms, carrying sheave assemblies, and platforms. At the top section of the supporting column, the return bullwheel is mounted by means of a screw flange joint. The return bullwheel is a weldment with spoke bracing and a rubber lined groove. There is a safety rim at the bottom side of the wheel to prevent the rope slipping and also to stabilise carrier assembly. Assemblies and the return bullwheel can be accessed by means of a ladder and service platforms with handrails.

As an option, the terminal can also be delivered as an embarking terminal, and/or as a tensioning one and placed at the bottom.

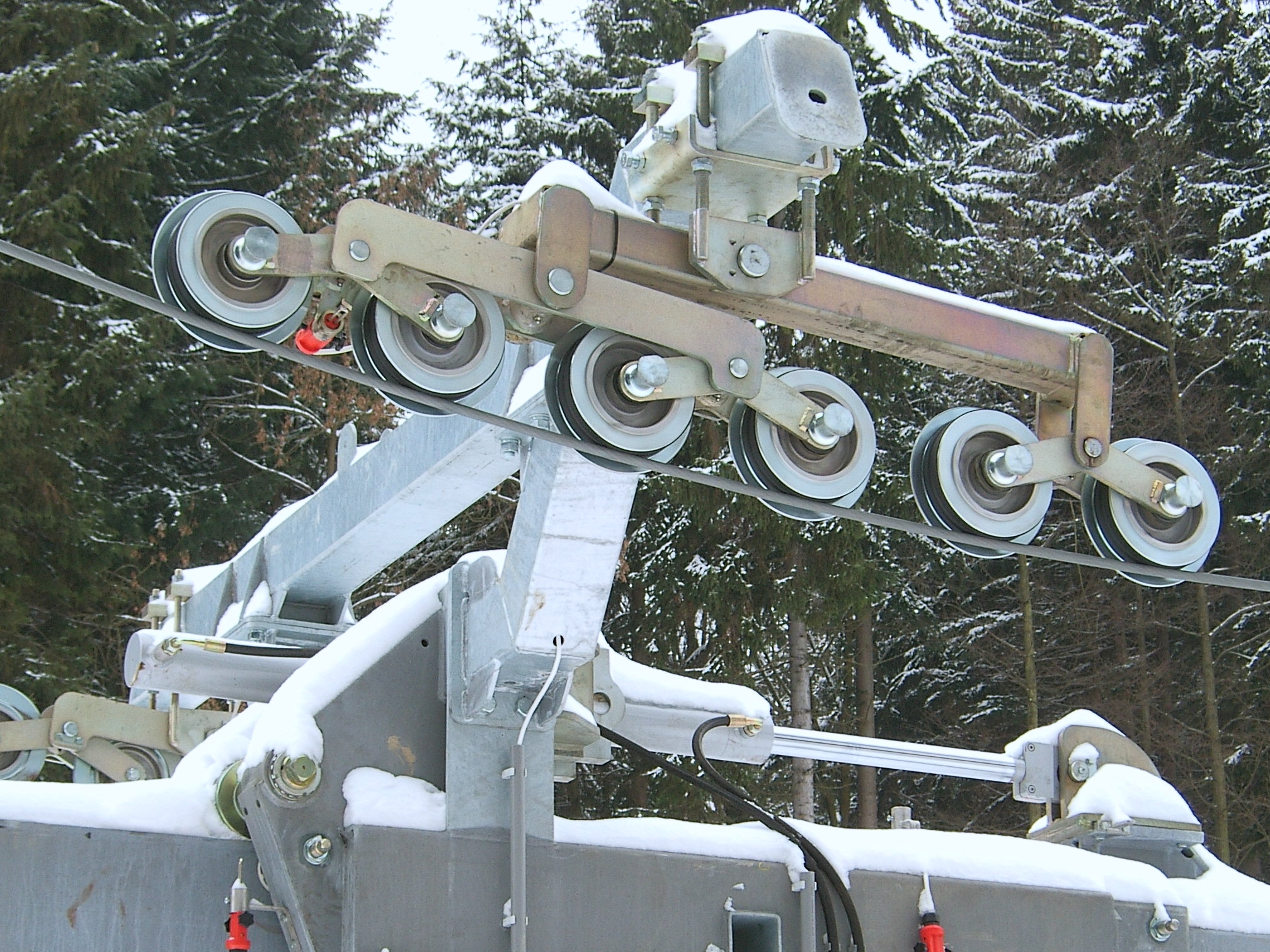

Support tower

The inclined “T-shape" support tower consists of a steel supporting column, anchored into an independent concrete slab, and a column head, to which sheave trains are attached. At the top section of the supporting column, service platforms are mounted. Platforms and sheave assemblies can be reached by a ladder.

Sheave trains

Sheave trains/assemblies have the role of guiding the line at the support tower. A sheave train consist of an appropriate number of rubber lined Ø200mm sheaves. Sheave trains on both lines of the lift are furnished with a safety device to detect rope coming off the wheels – a brittle bar.

References

Strážné ski area, Krkonoše - 45 kW, capacity 1200 persons/h, drive and tensioning terminal at the top

• JEŠTĚD sports grounds - Pod lany, Liberec, Jizerské Mountains - 45 kW, capacity 1156 persons/h, drive and tensioning terminal at the bottom

• Boží Dar ski area – Neklid - Pod hranicí, Krušné Mountains - 30 kW, capacity 1226 persons/h, drive and tensioning terminal at the bottom

• Potůčky ski area, Krušné Mountains - 45 kW, capacity 1200 persons/h, drive and tensioning terminal at the bottom

• Kašperské Mountains ski area, Šumava - 37 kW, capacity 1143 persons/h, drive and tensioning terminal at the bottom

• Hlinsko SKI club, Českomoravská vrchovina - 37 kW, capacity 1193 persons/h, drive and tensioning terminal at the bottom

• Olešnice na Moravě ski area, Českomoravská vrchovina - 45 kW, capacity 1031 persons/h, drive and tensioning terminal at the bottom

• Šacberk ski area, Jihlava, Českomoravská vrchovina - 37 kW, capacity 1200 persons/h, drive and tensioning terminal at the bottom

• Velké Meziříčí SKI Club, Českomoravská vrchovina - 22 kW, capacity 919 persons/h, drive and tensioning terminal at the top

• Šindelná ski area, Kouty nad Desnou, Jeseníky - 45 kW, capacity 937 persons/h, drive and tensioning terminal at the bottom

• Přívrat ski area, Orlické Mountains - 30 kW, capacity 1200 persons/h, drive and tensioning terminal at the bottom

• Baba Pezinok ski area, Little Carpathians , SK - 37 kW, capacity 1200 persons/h, drive and tensioning terminal at the top

• Kálnica ski Centre, Povážský Inovec, SK - 45 kW, capacity 1200 persons/h, drive and tensioning terminal at the bottom

• Arłamów, Eastern Carpathians, PL - 37 kW, capacity 1165 persons/h, drive and tensioning terminal at the top