Search term must have more than 2 characters.

Specification

There are two basic models:

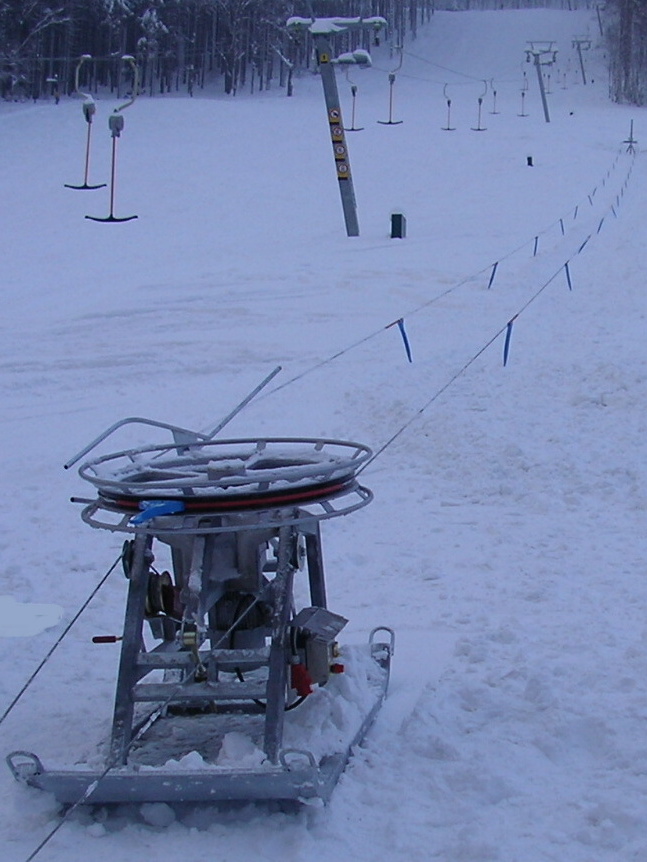

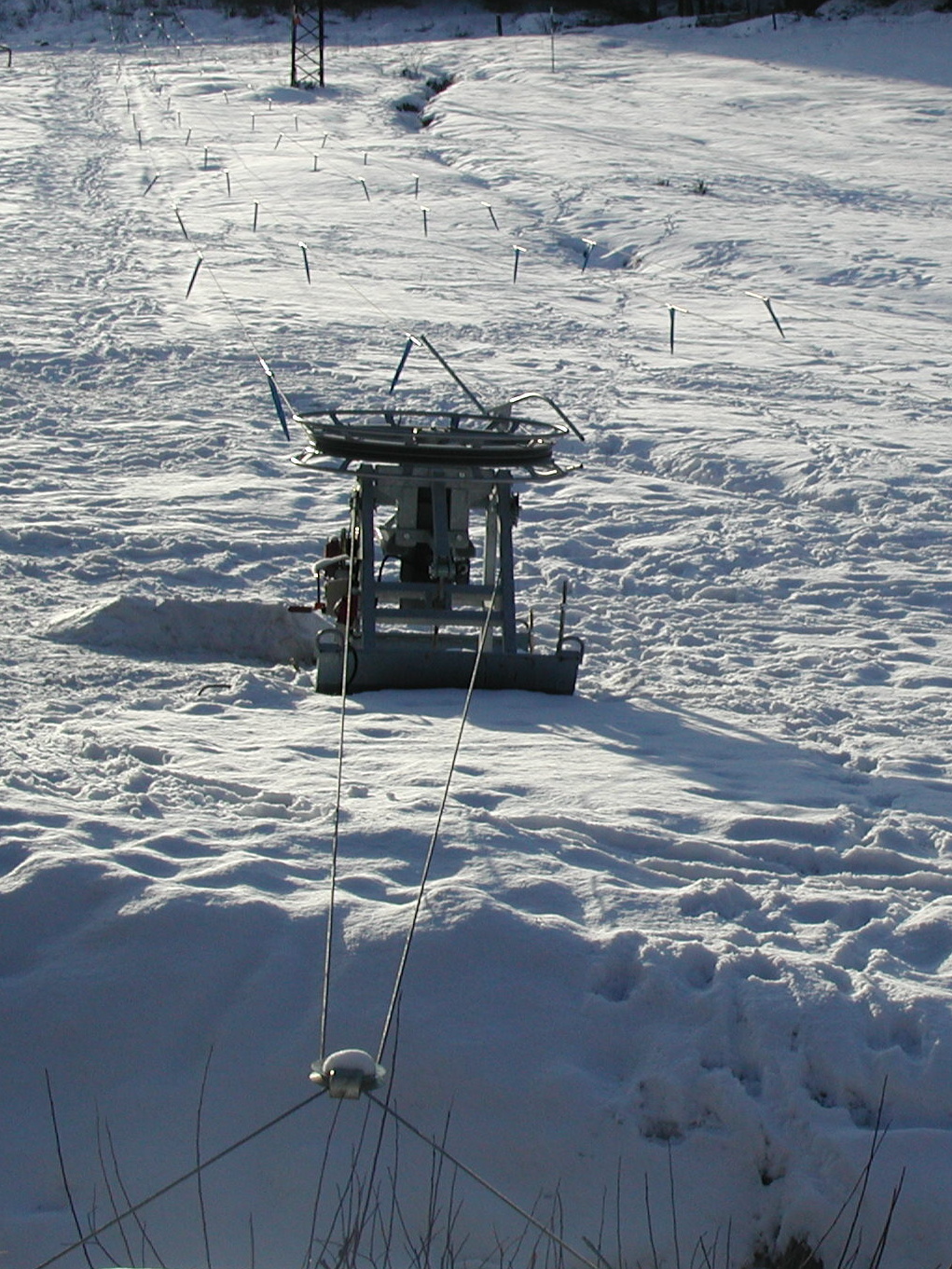

KINDLE PL – a 16-mm-dia polypropylene rope with vulcanised rubber pads for better grip on the rope is used to tow skiers

KINDLE OL – an 8-mm-dia steel rope with single plastic carriers used for towing skiers. The rope has a rubber band in the area where the skier holds the rope. Contrary to KINDLE PL, the OL model is furnished with guide devices at both terminals to stabilise the carriers.

ski lift effective transport distance | up to 150 m (depending on the terrain) |

elevation difference between terminals | up to 30 m (depending on ski lift type) |

drive and return bullwheel diameter (rubber lined) | 1.0 m |

distance of ropes along the line | 1.0 m |

tensioning | mechanical - 900 daN |

carriers | single |

drive output | 4.0 kW |

haul rope - PL / OL | Ø 16 mm, polypropylene / Ø 8 mm, galvanised steel |

conveying speed | continuously adjustable 0.5 – 1.46 m/s |

lift capacity | max. 600 persons/h (depending on ski lift type) |

surface finish of steel parts | hot-dip galvanized |

Technical description

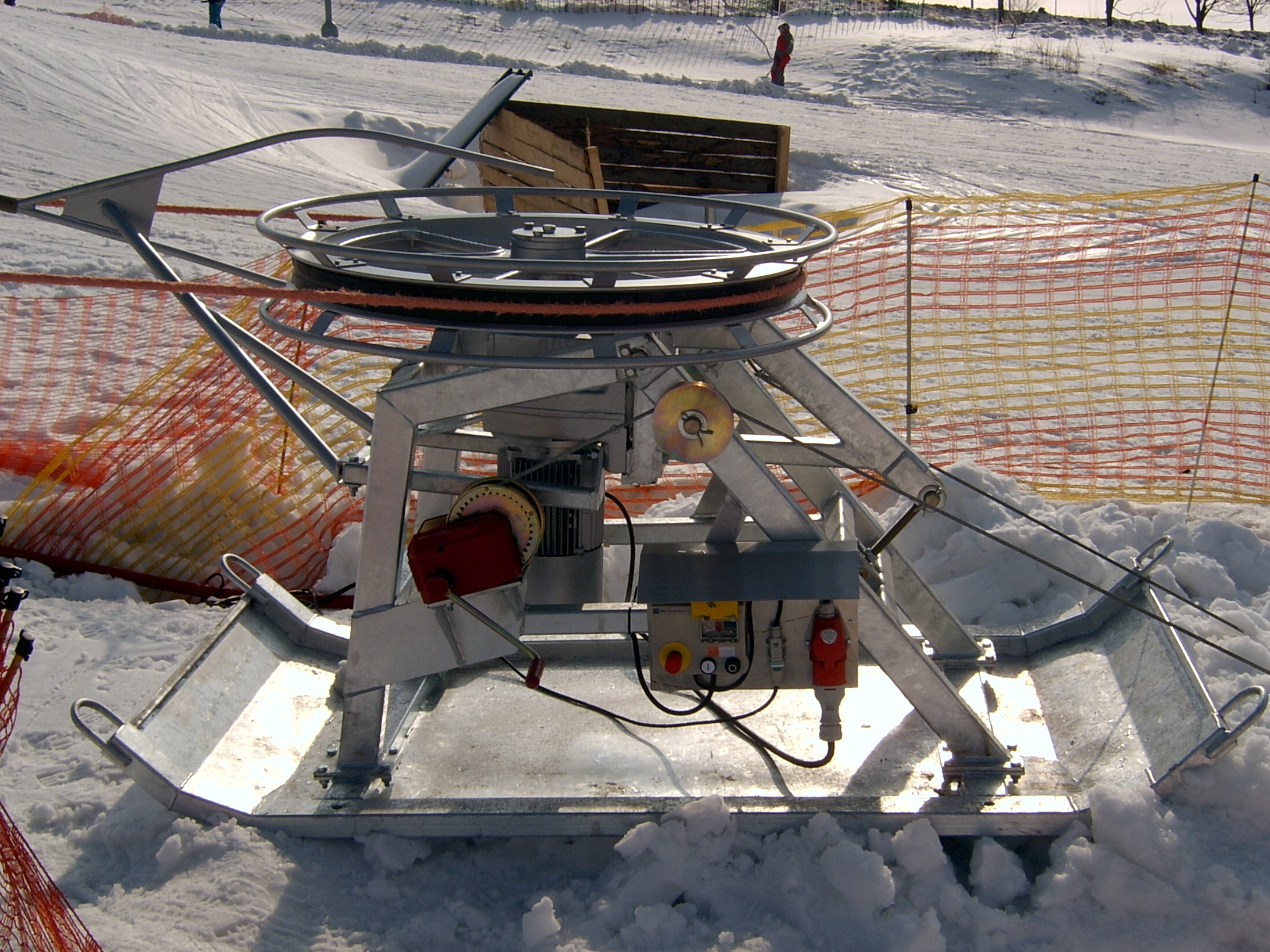

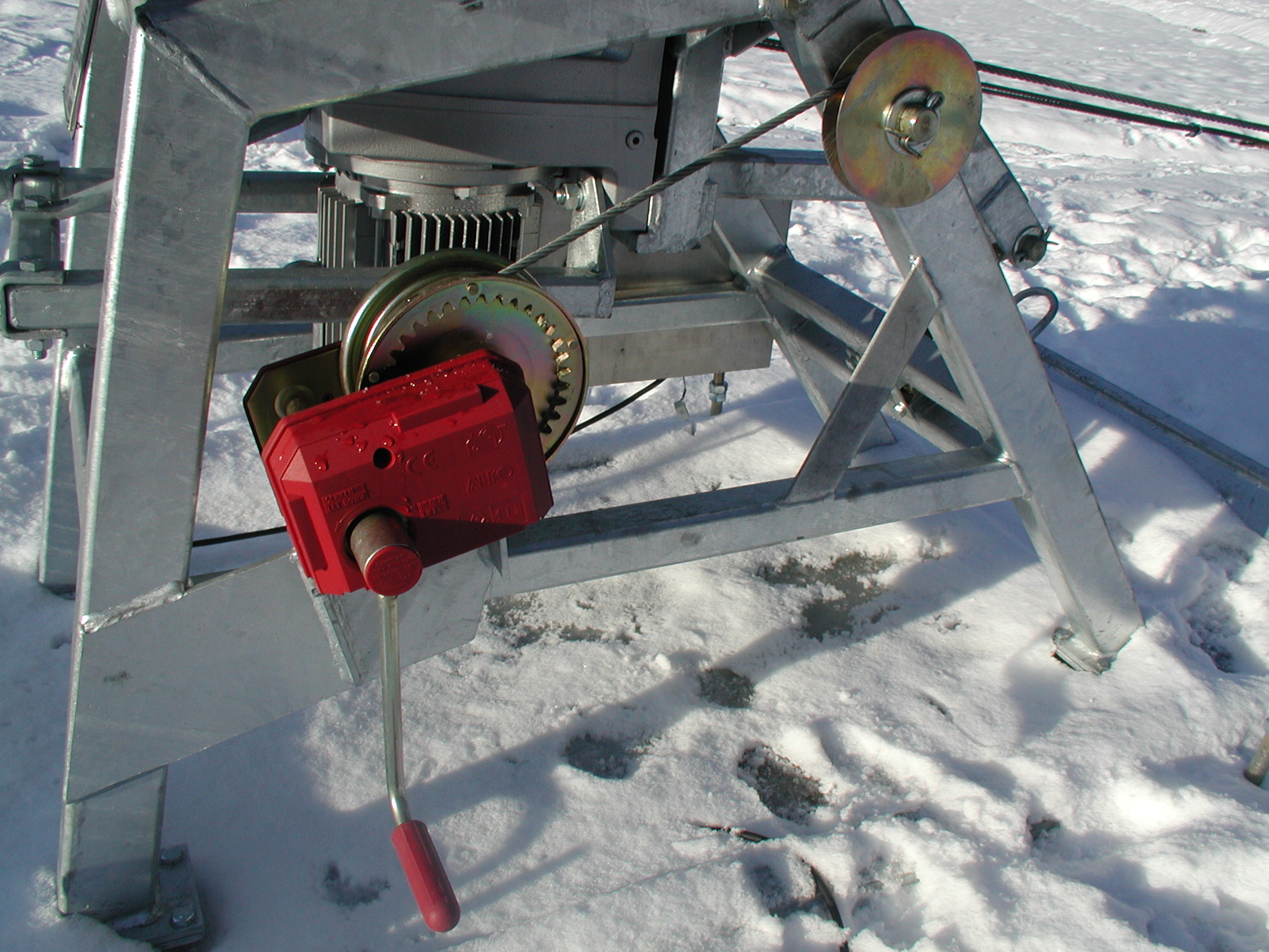

Drive terminal

Is always placed at the bottom and is used for tensioning and passenger embarking.

It is a simple steel structure furnished with skids at the bottom to make its shifting along a slope easier. There is a hinged frame, to which the drive and drive bullwheel are mounted. Pulling forces in the haul rope are captured by anchor ropes attached to anchor plates that are mechanically fixed in the ground behind the terminal. A mechanical winch is used for tensioning the rope. The drive unit is furnished with an anti-roll back device. The drive bullwheel is seated on the gear box output shaft and is made of aluminium alloy. Its rope groove is rubber lined. There are safety rims at the top and bottom sides of the wheel to prevent rope slipping.

Return terminal

It is always fixed and placed at the top and used for disembarking.

It consists of anchoring bits, a supporting pillar and an arm holding the return bullwheel. The return terminal supporting column stands on anchoring plates that are mechanically fixed to the ground. Pulling forces in the haul rope are captured by anchor ropes. The terminal’s angle can be adjusted by tilting the supporting column – by means of shortening (or prolonging) the anchor rope and/or by tilting the return bullwheel arms over two take-up screws. The height of the terminal can be adjusted by shifting the pegs of the arm and take-up screws to one of the three remaining positions, holes in the supporting column. The return bullwheel is made of aluminium alloy and the rope groove is rubber lined. The return bullwheel is seated on re-greasable antifriction bearings. There is a safety rim at the bottom side of the wheel to prevent rope slipping.

• Bouřňák Sport Centre, Krušné Mountains - type OL, capacity 600 persons/h

• ŠPIČÁK ski area, Šumava - type PL, capacity 500 persons/h

• Lipno ski area, Šumava - type PL, capacity 507 persons/h

• SKiMU Sport Centre, Horní Malá Úpa, Krkonoše - type OL, capacity 720 persons/h

• Petrova bouda, Špindlerův Mlýn, Krkonoše - type OL, capacity 521 persons/h

• Peklák ski area, Česká Třebová, Orlické Mountains - type OL, capacity 600 persons/h

• Přemyslov ski area, Jeseníky - type OL, capacity 529 persons/h

• Lázeňský vrch ski area, Lipová-Lázně, Jeseníky - type OL, capacity 507 persons/h

• TROJÁK ski area, Rajnochovice, Hostýnské vrchy - type PL, capacity 500 persons/h

• Šibeniční vrch Mnichovice ski area, Středočeská pahorkatina - type OL, capacity 507 persons/h

• Racibor SKI PARK, Oravský Podzámok, Oravská vrchovina, SK - type OL, capacity 507 persons/h